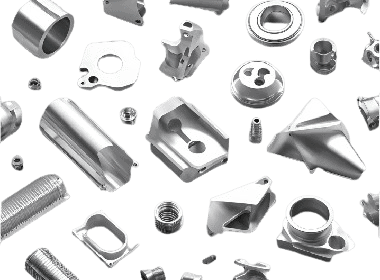

Aluminum Castings

Welcome to our aluminum casting manufacturing hub, where precision meets strength. Explore our diverse range of aluminum casting solutions, meticulously crafted to meet industry standards and your unique specifications. From alloy selection to final inspection, we ensure the highest quality at every step. Trust us to bring your vision to life with durable, reliable, and precisely engineered aluminum castings. Discover the excellence that defines us - your trusted partner in aluminum-casting innovation.

Green Sand Casting

Green sand casting is a method that involves using a mixture of sand, clay, and water to create molds. The mold is created by packing the mixture around a pattern, which is then removed to create a cavity for casting. Molten metal is poured into the cavity, and the mold allows for the creation of complex intricate designs. After solidification, the sand mold is broken to retrieve the finished cast part. Green sand casting is cost-effective and versatile, making it suitable for parts in the automotive, machinery, and agriculture industries.

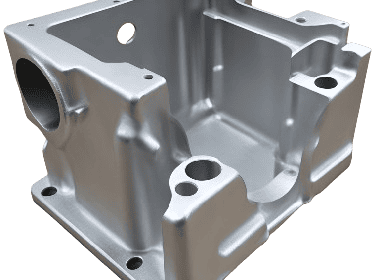

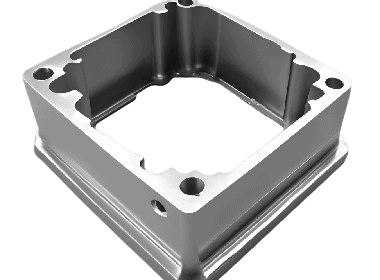

Permanent Mold Casting

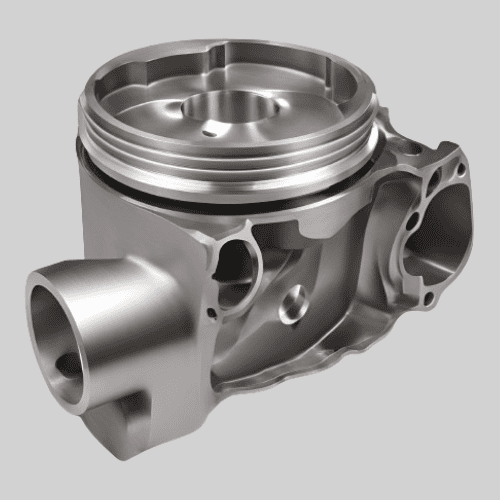

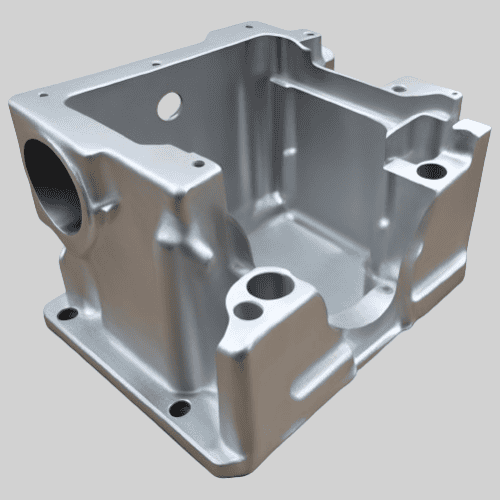

Permanent mold casting uses steel or other metal molds and cores. Strong castings are formed by pouring aluminum into the mold. Permanent molds create highly repeatable parts with consistency. Their rapid cooling generates a more consistent microstructure, which improves mechanical properties significantly. Permanent mold (gravity die) casting is best suited for high volumes. These are typically larger than die castings. The weight of permanent mold castings usually is up to 10 kg. Impellers, Wheels, pump parts, and compressor parts are a few examples.

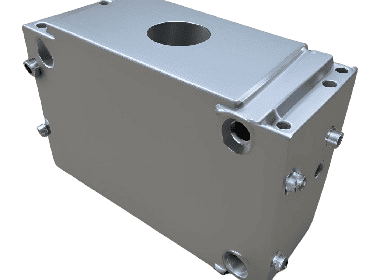

Die Casting

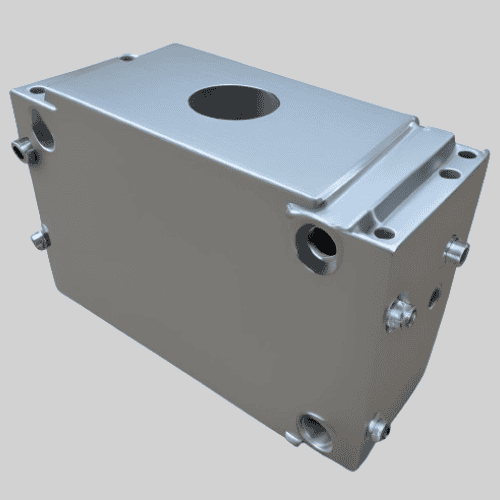

Die casting maintains close tolerances to produce good surface finishes and is best designed with uniform wall thickness. These are made by injection of molten metal into metal molds under pressure. Rapid injection and solidification under high pressure produce a dense, fine-grain surface structure, which results in excellent robust properties. It is suited to the production of large quantities of small parts up to 5kg common. Automotive, HVAC, Pumps, Pharmacy & several others require such parts.

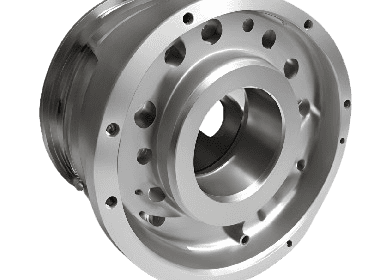

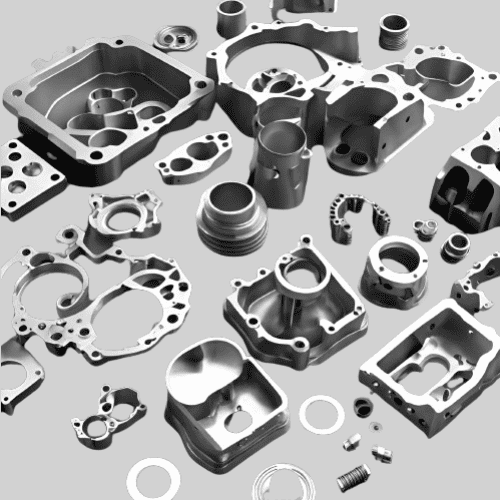

Aluminum Casting

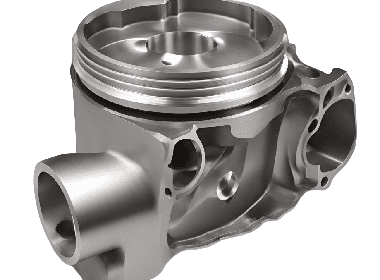

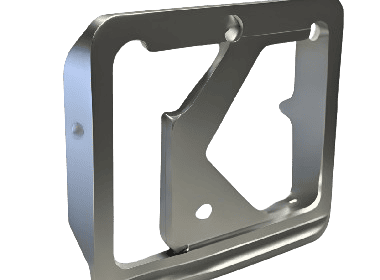

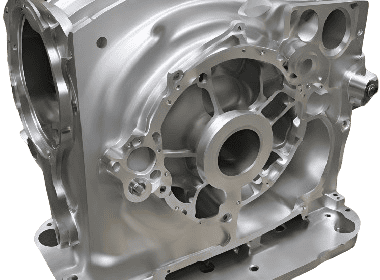

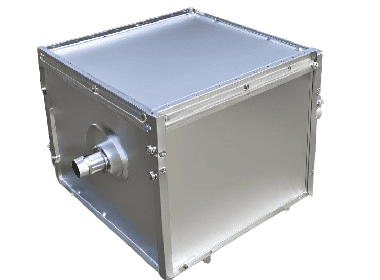

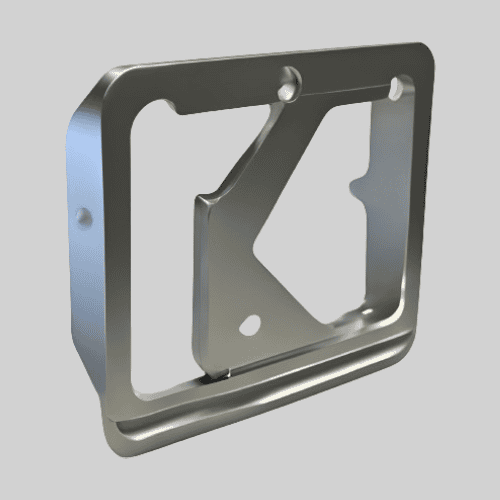

Alloy Bracket

Alloy Casting

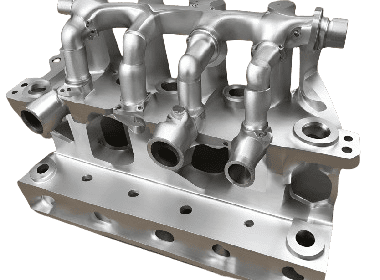

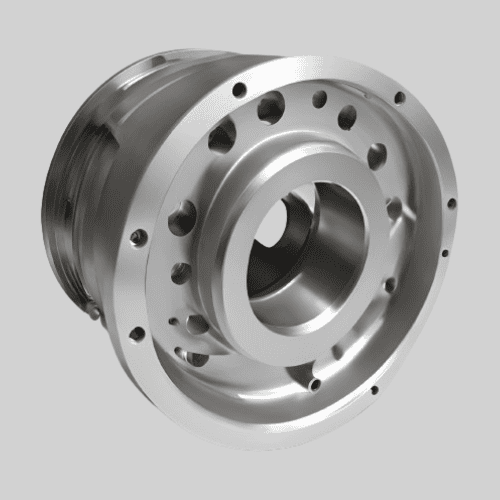

Alloy Fly Wheel

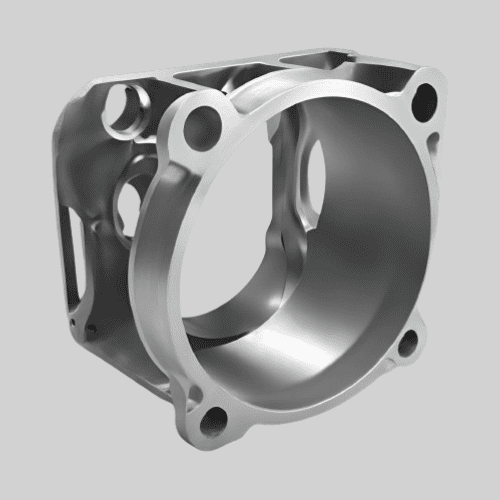

Alloy Housing

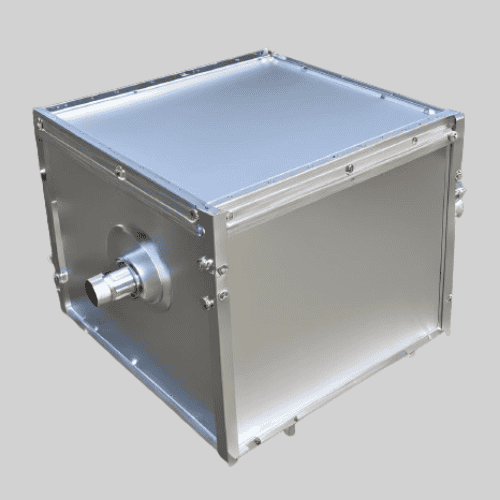

Alloy RF Filter Box Assembly

Auto Part

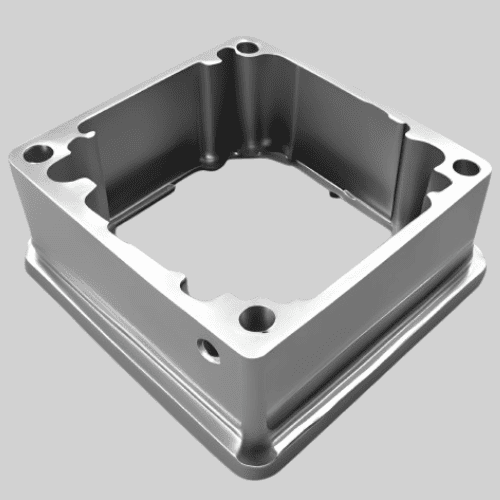

Auto Stand

Die Cast Parts

Electric Enclosure

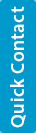

Manifold

Transmission Component

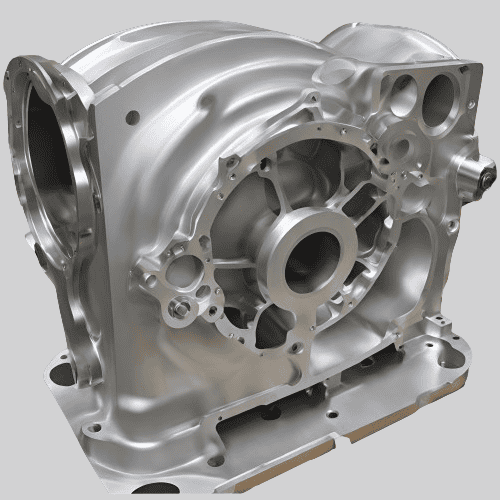

Transmission Housing

Aluminium Grades

Different grades of aluminium are identified using four-digit numbers with the first number denoting the series of grade, indicating the primary alloying element as per the International Alloy Designation System. Properties can be modified with heat-treatment or other processes.

1000 Series – “Pure” Aluminium

The purest, with excellent workability and are a versatile choice, suitable for hard forming, spinning and welding. These alloys are highly resistant to corrosion and have excellent thermal and electrical conductivity. and are used in food processing and packaging, chemical storage and electrical transmission applications.

2000 Series – Copper Alloys

These can be heat-treated to give them outstanding toughness and hardness, comparable to some steels. They have excellent machinability and a great strength-to-weight ratio; the combination of these characteristics makes them a popular choice in the aerospace industry.

Their low corrosion resistance, so they are often painted or clad with a higher purity alloy.

3000 Series – Manganese Alloys

These have moderate strength, corrosion resistance and good workability. The most widely used aluminium alloys of all, 3003, popular due to its versatility, excellent weldability and aesthetically pleasing finish, for production of cooking utensils, signs, treads, storage and sheet-metal applications such as roofing and guttering.

4000 Series – Silicon Alloys

Silicon is used to lower melting point of material whilst keeping its ductility. Alloy 4043 is used for welding wire, suitable for use in elevated temperatures and offering a smoother finish than many other options.Good thermal and electrical conductivity and corrosion resistance, make these alloys a popular choice in automotive segment.

5000 Series – Magnesium Alloys

These highly versatile alloys maintain moderate strength, weldability and respond well to working and forming. These offer exceptional corrosion resistance, making them a popular choice for marine applications such as boat hulls and other industry-specific uses including storage tanks, pressure valves and cryogenic tanks.

6000 Series – Magnesium and Silicon Alloys

These alloys are used for general purpose uses in a huge variety of industries such as construction, architecture, automobile and more. With above-average strength, strong corrosion resistance and good machinability, materials in this series also respond well to heat-treatment and maintain their workability after tempering or annealing.

7000 Series – Zinc Alloys

Zinc as their primary agent, with a smaller ratio of magnesium or other metals included to help retain some workability. This combination results in an extremely hard, strong, stress-resistant metal. These alloys are commonly used in aerospace industries due to their superb strength-to-weight ratio, as well as for sports equipment and car bumpers.

8000 Series – Other Alloy Categories

The 8000 series are alloyed with a variety of other elements such as iron and lithium. Generally, they are created for very specific purposes within specialist industries such as aerospace and engineering. They offer similar properties to the 1000 series but with higher strength and formability.

Characteristics Of Aluminium Casting Alloys:

Here at Calmet, our goal is to manufacture and deliver products as per the requirements considering their speciation given at the time of ordering. It’s not about the details alone but we also cooperate and put in our expertise and capabilities to ensure the most superior quality products are delivered to the customer.

| Specification (AA) | 514 | A413 | A360 | 222 | A380 | A356 | 712 |

|---|---|---|---|---|---|---|---|

| Tensile Strength (N/mm2) | 140-170 | 160-190 | 95-120 | 170 | 180 | 130-150 | 215 |

| Elongation (%) | 3 | 5 | 05-Mar | 2 | 1.5 | 2 | 4 |

| Brinell Hardness | 50-70 | 50-55 | 75-85 | 85 | 85 | 55-65 | 70 |

| Density (g/cm3) | 2.65 | 2.65 | 2.68 | 2.7 | 2.79 | 2.68 | 2.81 |

| Freezing range (deg C) | 642-580 | 575-565 | 575-550 | 620-550 | 580-520 | 615-550 | 615-570 |

| Thermal Con @ 25degC (cal/cm2/cm/deg C) | 0.33 | 0.34 | 0.35 | 0.34 | 0.23 | 0.36 | 0.35 |

| Electrical Con @ 20degC (% Copper Standard) | 31 | 37 | 38 | 39 | 24 | 39 | 35 |

| Machinability | Excellent | Poor | Fair | Good | Good | Good | Good |

| Corrosion Resistance | Excellent | Excellent | Good | Good | Fair | Excellent | Excellent |

| Electro Plating Suitability | F (2) | F (1) | F (1) | F (1) | Fair | Fair | Fair |

| Non Spark | No | No | No | No | No | No | No |

| Casting Characteristics - Sand Casting | Fair | Excellent | Good | Good | Fair | Excellent | Good |

| Casting Characteristics - Gravity Die Casting | Fair | Excellent | Good | Good | Fair | Excellent | Fair |

| Casting Characteristics - High Pressure Die Casting | Fair | Good | * | * | Excellent | Good | Fair |

1 - These alloys, containing Silicon, require a modification treatment for good adhesion

2 - Can be plated, but not recommend

Industries and Applications:

| Grade | Application |

|---|---|

| A05140 | Commonly used for casting applications that require good corrosion resistance and high strength, making it suitable for marine components, pump housings, and valve bodies. |

| A04013 | Known for its excellent castability and weldability, making it ideal for creating intricate cast components such as automotive parts, heat exchangers, and electrical enclosures. |

| A03600 | Utilized in casting processes where high machinability and good corrosion resistance are essential, making it suitable for producing components like hydraulic manifolds, instrumentation components, and pressure vessels. |

| A03550 | Favored for its combination of high strength and thermal conductivity, making it suitable for casting applications such as heat sinks, motor housings, and automotive transmission components. |

| A03800 | Used in casting applications that require a good balance of strength, ductility, and corrosion resistance, making it suitable for manufacturing components such as aircraft parts, pump bodies, and hydraulic cylinders. |

| A03560 | Known for its excellent castability and weldability, making it a popular choice for casting components such as automotive engine blocks, cylinder heads, and structural parts in the aerospace industry. |

| A03280 | Used for casting applications where high strength and wear resistance are crucial, making it suitable for producing components like gears, bearing housings, and machine tool parts. |

| A03100 | Known for its high thermal conductivity and good corrosion resistance, making it suitable for casting applications that require heat dissipation, such as heat exchangers, electronic enclosures, and lighting fixtures. |

Complete Solutions:

3- Stage Quality Control Process & Inspection:

- The quality assessment process with special testing equipment ensures only the finest products reach the buyers and customers.

- Here at Calmet, all the employees receive in-depth trainning, guidance, and potential elevation from the mentors or immediate managers who are always observant of the continuous progress and Lean philosophy (Kaizen).

- This intensive process ensures that the employees are well-equipped with the knowledge and work techniques as per their role in the organization.

- This task and its needed output will be perfect if performed with thorough understanding. It's crucial for our quality department to look in and stringently advise on any necessary changes to be made to ensure the scope of errors is minimized or removed.

Raw material

- Immersion Spectrometer with 24 Elements

- Sand Testing Facilities

- Universal Tensile Testing Machine

- Image Analyzer

- On-line Mould checking Facilities

Dimensional

- Coordinate Measuring Machine (CNC-CMM) – Range: 1m x 1m

- Linear Measuring Machine (LMM) – Range: 1m x 1m

- Profile Projector

- Digital Height Gauge – Range: 1m

- All kinds of Inspection Gauges & Instruments

Specialized

- Non-Destructive Test (X-ray)

- Ultrasonic Test

- Dye Penetrant Test

- Hydro Test

- Millipore Cleanliness Test

- Static Balancing

Case Studies

Challenge

The customer encountered significant challenges with their previous aluminum casting processes, which included [list specific problems such as poor quality, high rejection rates, long production times, or excessive costs]. These issues hindered their ability to meet market demands and maintain competitive advantage.

Solution

Our team at Calmet partnered with customer’s technical department to provide a customized aluminum casting solution. The key steps in our approach were:

Initial Consultation: Conducting in-depth discussions to fully understand the client’s specific needs and challenges.

Design Optimization: Utilizing advanced CAD and simulation tools to optimize the design for manufacturability and performance.

Material Selection: Choosing the best aluminum alloys to ensure superior strength, durability, and lightweight properties.

Casting Process: Implementing state-of-the-art casting techniques, including [specific techniques like sand casting, die casting, or permanent mold casting].

Quality Assurance: Employing stringent quality control measures, including X-ray inspection, metallurgical analysis, and dimensional verification.

Results

Enhanced Quality: The new casting process resulted in components with superior mechanical properties and dimensional accuracy, reducing the rejection rate by 1.74%.

Cost Efficiency: By optimizing the casting process, we achieved significant cost savings for customer, amounting to about 4%.

Reduced Lead Time: Streamlined production processes led to a reduction in lead time by over two weeks, enabling faster delivery to market.

Sustainability: Implementing eco-friendly practices reduced waste and improved the overall sustainability of the production process.

Why Calmet?

To maintain a competitive advantage in the aluminium casting industry, Calmet always evaluates its unique strengths and value proposition. Here are some factors to consider while analyzing the competitive advantage that Calmet offers:

Quality and Expertise

- Expertise and experience in specialized casting processes, such as investment casting or sand casting, provide an edge over competitors.

- Certification of quality standards, adherence to industry-specific regulations, and continuous improvement initiatives have immensely helped Calmet and its customers.

Technological Capabilities

- Cutting-edge technology and equipment that Calmet employs significantly enhance the efficiency and quality of the manufacturing process.

- Investment in advanced machinery, automation, and digital tools can lead to cost savings, faster production cycles, and better casting outcomes.

- Strong R&D capabilities to develop new alloys and casting methods can differentiate a firm from its competitors and attract customers seeking innovative solutions.

Supply Chain Management

- Efficient supply chain management, including sourcing raw materials, logistics, and inventory control, can optimize costs and lead times.

- Building reliable relationships with suppliers and ensuring a steady supply of high-quality raw materials can give the firm an advantage in meeting customer demands promptly.

- Implementing just-in-time manufacturing practices and adopting lean principles can enhance competitiveness by minimizing waste and maximizing efficiency.

Customer Relationships

- Developing strong customer relationships and providing exceptional customer service is a way of life at Calmet. Every employee is dedicated to this philosophy.

- Understanding customer requirements, providing technical support, and offering customized solutions have helped us stand ahead of competitors.

- Regular communication and engagement with customers to gather feedback and address concerns helps in continuous improvement and maintaining a competitive edge.

Cost Efficiency

- To remain competitive, controlling costs throughout the manufacturing process is crucial at Calmet.

- Implementing cost-effective production strategies, optimizing resource utilization, and managing overhead expenses helps minimize costs.

- Continuous evaluation of cost drivers and exploring opportunities to enhance operational efficiency contribute to long-term profitability and competitive advantage.

Sustainable Manufacturing

Sustainable manufacturing focuses on minimizing the environmental impact and maximizing resource efficiency throughout the manufacturing process using the below commonly used techniques:

- Energy Efficiency: Implementing energy-efficient measures like optimizing furnace operations, adopting energy-saving technologies, and utilizing renewable energy sources.

- Waste Management: Implementing effective waste management techniques, including recycling and reusing materials, reducing waste generation, and implementing proper disposal methods.

- Resource Conservation: Employing techniques to reduce water consumption, optimize raw material usage, and minimize emissions.

- Supply Chain Transparency: Ensuring transparency and responsibility in the supply chain, such as sourcing materials from sustainable suppliers and monitoring the social and environmental impacts of the supply chain.

New Technologies

Innovative technologies can revolutionize the aluminium casting manufacturing industry, enhancing efficiency, quality, and customization capabilities. Some notable advancements at Calmet include:

- 3D Printing: The introduction of 3D printing in aluminium casting allows for complex shapes and design optimization, reducing material waste and lead times while enabling customization.

- Automation and Robotics:Integration of automation and robotics streamlines production processes, enhances precision, improves safety, and increases productivity.

- Data Analytics and AI: Leveraging data analytics and artificial intelligence can enhance quality control, predictive maintenance, and process optimization, resulting in improved efficiency, reduced costs, and enhanced product quality.

- Augmented Reality (AR): AR technology can assist in training, remote maintenance and repair, and real-time quality assurance, improving operational efficiency and reducing downtime.

Industry Regulations

The aluminium-casting manufacturing industry is subject to various regulations, which ensure safety, quality, and environmental compliance. Key regulations may include:

- Workplace Safety: Regulations governing occupational health and safety, including maintaining safe working conditions, providing proper protective equipment, and adhering to workforce safety standards.

- Environmental Compliance: Regulations related to emissions control, waste management, pollution prevention, and resource conservation to mitigate the environmental impact of operations.

- Quality Standards: Compliance with quality certifications such as ISO 9001 ensures that products and processes meet internationally recognized quality standards, fostering customer trust.

- Supply Chain Traceability: Regulations and standards may require documentation and traceability of raw materials, ensuring responsible sourcing and avoiding materials with ethical or environmental concerns.

Keeping abreast of these regulations and proactively implementing compliance measures helps a firm maintain its reputation, enhance customer confidence, and demonstrate commitment to sustainability.