Welcome to our metal fabrication division, where craftsmanship meets innovation. We specialize in transforming raw metals into high-quality components tailored to your unique specifications. Our comprehensive suite of services includes cutting, bending, welding, and assembling, ensuring precision and durability in every project. Serving industries such as construction, automotive, aerospace, and energy, we are committed to delivering solutions that meet the highest standards of quality and performance.

Partner with us to bring your concepts to life with reliability and excellence. It begins with Design and Engineering with CAD software for detailed blueprints, considering material selection, strength requirements, and cost. Our Metal Fabrication Components stand a class apart with adherence to the following:

- Dimensions and tolerances accurately maintained as specified.

- Surface finish is smooth, uniform, and consistent.

- The part is free from defects such as cracks, warping, or porosity.

- Uniform material properties are throughout the component.

- Application of right heat treatment or surface coatings.

- Ensuring the components possess the strength and durability needed for its intended use.

- Corrosion resistance meets the demands of the application.

- Welded assemblies exhibit proper joint integrity and quality.

- The product adheres to all applicable industry standards and regulations.

PROCESSES:

Welding & Joining Solutions - Offering comprehensive welding services for robust metal integration.

MIG & TIG Welding – Precision techniques for diverse applications.

Arc & Robotic Welding – Automated solutions for high-volume production.

Applications: Structural assemblies, machine components, pipelines.

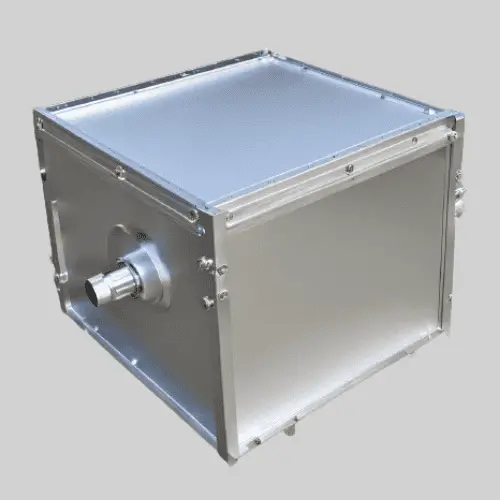

Precision Machining & CNC Fabrication - CNC services deliver high-accuracy parts.

CNC Milling & Turning – Efficient production of complex components.

Boring & Grinding – Precision finishing for exact specifications.

Applications: Aerospace components, hydraulic systems.

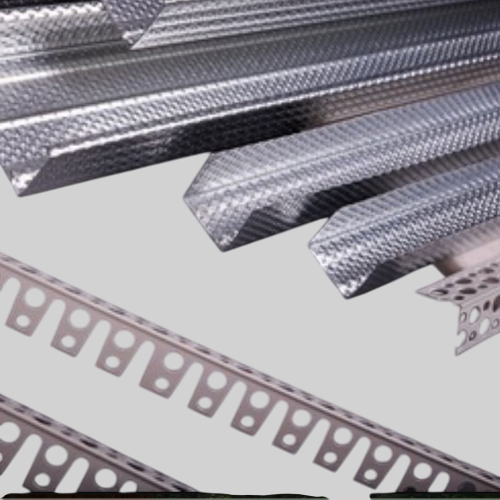

Metal Cutting & Forming - Utilizing advanced techniques, we shape metals effectively.EWM News

Laser & Plasma Cutting – Accurate cuts for intricate designs.

Waterjet Cutting – Cold cutting suitable for sensitive materials.

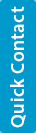

Bending & Rolling – Crafting enclosures and structural parts.

Applications: Machine enclosures, automotive parts.

Assembly & Integration - Comprehensive assembly services for seamless component integration.

Mechanical Assembly – Full and sub-assembly solutions.

Testing & Inspection – Ensuring accuracy and performance.

Applications: Railway components, industrial machinery.

Surface Treatment & Finishing - Enhancing durability and aesthetics.

Powder Coating & Painting – Protective finishes for longevity.

Plating – Nickel, zinc, chrome for corrosion resistance.

Applications: Automotive chassis, marine components.

METAL FABRICATION

MATERIALS WE WORK WITH

We fabricate components using high-grade metals, ensuring strength, durability, and performance.

SPECIAL SOLUTIONS:

3-STAGE QUALITY CONTROL PROCESS & INSPECTION:

- The quality assessment process with special testing equipment ensures only the finest products reach the buyers and customers.

- Here at Calmet, all the employees receive in-depth trainning, guidance, and potential elevation from the mentors or immediate managers who are always observant of the continuous progress and Lean philosophy (Kaizen).

- This intensive process ensures that the employees are well-equipped with the knowledge and work techniques as per their role in the organization.

- This task and its needed output will be perfect if performed with thorough understanding. It's crucial for our quality department to look in and stringently advise on any necessary changes to be made to ensure the scope of errors is minimized or removed.

Raw material

- Immersion Spectrometer with 24 Elements

- Sand Testing Facilities

- Universal Tensile Testing Machine

- Image Analyzer

- On-line Mould checking Facilities

Dimensional

- Coordinate Measuring Machine (CNC-CMM) – Range: 1m x 1m

- Linear Measuring Machine (LMM) – Range: 1m x 1m

- Profile Projector

- Digital Height Gauge – Range: 1m

- All kinds of Inspection Gauges & Instruments

Specialized

- Non-Destructive Test (X-ray)

- Ultrasonic Test

- Dye Penetrant Test

- Hydro Test

- Millipore Cleanliness Test

- Static Balancing

CASE STUDIES – PRECISION FABRICATION FOR HEAVY EQUIPMENT MANUFACTURER

Case Study

- Client:

- A leading heavy equipment manufacturer specializing in construction machinery.

- Project Overview:

- The client required custom-fabricated metal components for their latest line of excavators, emphasizing precision, durability, and timely delivery to meet their production schedule.

- Challenges:

- Complex Designs: The components featured intricate geometries demanding high precision.

- Material Specifications: Utilization of high-strength, wear-resistant steel alloys was necessary to withstand harsh operational conditions.

- Tight Deadlines: The client needed a rapid turnaround to align with their assembly line schedules.

- Solution:

- Calmet’s metal fabrication team collaborated closely with the client’s engineering department to fully understand the component specifications and performance requirements. Leveraging advanced CNC machining and precision welding techniques, Calmet ensured adherence to tight tolerances and complex designs. Additionally, a dedicated project management approach was implemented to streamline production processes and meet the stringent deadlines.

- Implementation Steps:

- Design Analysis: Reviewed the client’s designs to identify potential fabrication challenges and proposed enhancements for manufacturability.

- Material Procurement: Sourced high-quality, wear-resistant steel alloys that met the specified mechanical properties.

- Fabrication: Utilized state-of-the-art CNC machines for cutting and shaping, followed by precision welding to assemble the components.

- Quality Assurance: Conducted rigorous inspections, including dimensional checks and non-destructive testing, to ensure each component met the required standards.

- Logistics: Coordinated closely with the client’s supply chain team to ensure just-in-time delivery, minimizing storage needs and aligning with production schedules.

- Results:

- Enhanced Product Performance: The fabricated components exhibited superior durability and precision, contributing to the overall reliability of the excavators.

- On-Time Delivery: Calmet successfully met the tight deadlines, enabling the client to maintain their production timeline without delays.

- Cost Efficiency: Through optimized fabrication processes and effective project management, Calmet delivered high-quality components within the client’s budget constraints.

- Conclusion:

- By partnering with Calmet, the heavy equipment manufacturer benefited from expertly fabricated metal components that met their exacting standards. Calmet’s commitment to precision, quality, and timely delivery reinforced its position as a trusted partner in the metal fabrication industry.

WHY CALMET?

To maintain a competitive advantage in the metal fabrication industry, Calmet always evaluates its unique strengths and value proposition. Here are some factors to consider while analyzing the competitive advantage that Calmet offers:

Quality and Expertise

-

-

- Expertise and experience in specialized casting processes, such as investment casting or sand casting, provide an edge over competitors.

- Certification of quality standards, adherence to industry-specific regulations, and continuous improvement initiatives have immensely helped Calmet and its customers.

-

Technological Capabilities

-

-

- Cutting-edge technology and equipment that Calmet employs significantly enhance the efficiency and quality of the manufacturing process.

- Investment in advanced machinery, automation, and digital tools can lead to cost savings, faster production cycles, and better casting outcomes.

- Strong R&D capabilities to develop new alloys and casting methods can differentiate a firm from its competitors and attract customers seeking innovative solutions.

-

Supply Chain Management

-

-

- Efficient supply chain management, including sourcing raw materials, logistics, and inventory control, can optimize costs and lead times.

- Building reliable relationships with suppliers and ensuring a steady supply of high-quality raw materials can give the firm an advantage in meeting customer demands promptly.

- Implementing just-in-time manufacturing practices and adopting lean principles can enhance competitiveness by minimizing waste and maximizing efficiency.

-

Customer Relationships

-

-

- Developing strong customer relationships and providing exceptional customer service is a way of life at Calmet. Every employee is dedicated to this philosophy.

- Understanding customer requirements, providing technical support, and offering customized solutions have helped us stand ahead of competitors.

- Regular communication and engagement with customers to gather feedback and address concerns helps in continuous improvement and maintaining a competitive edge.

-

Cost Efficiency

-

-

- To remain competitive, controlling costs throughout the manufacturing process is crucial at Calmet.

- Implementing cost-effective production strategies, optimizing resource utilization, and managing overhead expenses helps minimize costs.

- Continuous evaluation of cost drivers and exploring opportunities to enhance operational efficiency contribute to long-term profitability and competitive advantage.

-

Sustainable Manufacturing

Sustainable manufacturing focuses on minimizing the environmental impact and maximizing resource efficiency throughout the manufacturing process using the below commonly used techniques:

-

-

- Energy Efficiency: Implementing energy-efficient measures like optimizing furnace operations, adopting energy-saving technologies, and utilizing renewable energy sources.

- Waste Management: Implementing effective waste management techniques, including recycling and reusing materials, reducing waste generation, and implementing proper disposal methods.

- Resource Conservation: Employing techniques to reduce water consumption, optimize raw material usage, and minimize emissions.

- Supply Chain Transparency: Ensuring transparency and responsibility in the supply chain, such as sourcing materials from sustainable suppliers and monitoring the social and environmental impacts of the supply chain.

-

New Technologies

Innovative technologies can revolutionize the metal fabrication manufacturing industry, enhancing efficiency, quality, and customization capabilities. Some notable advancements at Calmet include:

-

-

- 3D Printing: The introduction of 3D printing in metal fabrication allows for complex shapes and design optimization, reducing material waste and lead times while enabling customization.

- Automation and Robotics:Integration of automation and robotics streamlines production processes, enhances precision, improves safety, and increases productivity.

- Data Analytics and AI: Leveraging data analytics and artificial intelligence can enhance quality control, predictive maintenance, and process optimization, resulting in improved efficiency, reduced costs, and enhanced product quality.

- Augmented Reality (AR): AR technology can assist in training, remote maintenance and repair, and real-time quality assurance, improving operational efficiency and reducing downtime.

-

Industry Regulations

The metal fabrication manufacturing industry is subject to various regulations, which ensure safety, quality, and environmental compliance. Key regulations include:

-

-

- Workplace Safety: Regulations governing occupational health and safety, including maintaining safe working conditions, providing proper protective equipment, and adhering to workforce safety standards.

- Environmental Compliance: Regulations related to emissions control, waste management, pollution prevention, and resource conservation to mitigate the environmental impact of operations.

- Quality Standards: Compliance with quality certifications such as ISO 9001 ensures that products and processes meet internationally recognized quality standards, fostering customer trust.

- Supply Chain Traceability: Regulations and standards may require documentation and traceability of raw materials, ensuring responsible sourcing and avoiding materials with ethical or environmental concerns.

-